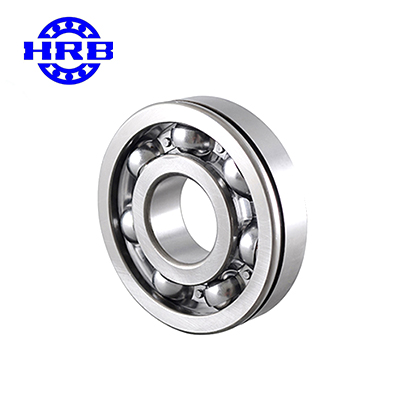

Tapered roller bearings are primarily employed to withstand combined radial and axial loads where radial loads predominate. Compared to angular contact ball bearings, they offer greater load-carrying capacity but lower limiting speeds. These bearings can accommodate axial loads in one direction and restrict axial displacement of the shaft or housing in that direction.

Single-row tapered roller bearings comprise an outer ring, an inner ring, and a set of tapered rollers enclosed within a cage-type retainer to form an inner ring assembly. The outer ring can be separated from the inner ring assembly. In accordance with ISO dimensional standards for tapered roller bearings, the outer ring or inner ring assembly of any standard size should be interchangeable internationally with the outer ring or inner ring assembly of the same size.

Typically, the taper angle of the outer ring raceway in single-row tapered roller bearings ranges from 10° to 19°, enabling them to simultaneously withstand combined axial and radial loads. A larger taper angle corresponds to greater axial load capacity. Bearings with a large taper angle are designated with a suffix “B”, featuring a taper angle between 25° and 29°, enabling them to withstand greater axial loads. Additionally, single-row tapered roller bearings permit adjustment of the clearance during installation.

In double-row tapered roller bearings, the outer ring (or inner ring) forms an integral unit. The two inner rings (or outer rings) have their small ends positioned close together, separated by a spacer ring. The clearance is adjusted by varying the thickness of this spacer ring, which can also be used to regulate the preload of the double-row tapered roller bearing.

Four-row tapered roller bearings exhibit performance characteristics largely identical to double-row tapered roller bearings. However, they can withstand greater radial loads than their double-row counterparts, though their maximum rotational speed is slightly lower. These bearings are primarily employed in heavy machinery applications.

“Do you see over yonder, dear client, those tricky equipment bottlenecks, those wear-and-tear troubles that stall your production? I intend to arm your machines with genuine imported bearings—and stand by with technical support to slay every glitch that comes your way.”

— Hengzhou Bearings

leave a comment