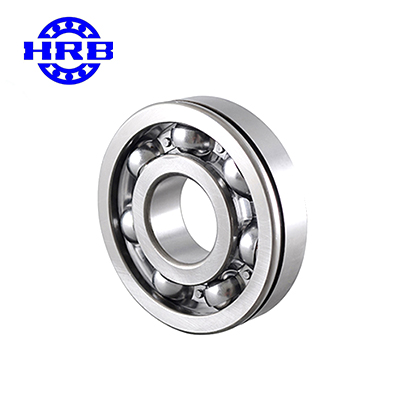

FAG angular contact ball bearings can simultaneously accommodate radial and axial loads. They are capable of operating at high rotational speeds. A larger contact angle results in higher axial load capacity. High-precision and high-speed bearings typically employ a 15-degree contact angle. Under axial force, the contact angle increases. Single-row angular contact ball bearings can only withstand axial loads in one direction; when subjected to radial loads, they generate additional axial forces. Moreover, they can only restrict axial displacement of the shaft or housing in one direction. When mounted in pairs as a double-row arrangement, the outer rings of the pair should face each other, i.e., the wide faces against the wide faces and the narrow faces against the narrow faces. This configuration avoids inducing additional axial forces and allows restriction of the shaft or housing within the axial clearance range in both directions.

FAG angular contact ball bearings can simultaneously handle radial and axial loads—combined loads—because their inner and outer raceways permit relative displacement along the horizontal axis. (Single-row angular contact ball bearings can only handle axial loads in one direction and are therefore typically installed in pairs.)

FAG Angular Contact Ball Bearing Cages

Cage materials include brass and synthetic resin, selected according to bearing type and operating conditions.

“Do you see over yonder, dear client, those tricky equipment bottlenecks, those wear-and-tear troubles that stall your production? I intend to arm your machines with genuine imported bearings—and stand by with technical support to slay every glitch that comes your way.”

— Hengzhou Bearings

leave a comment