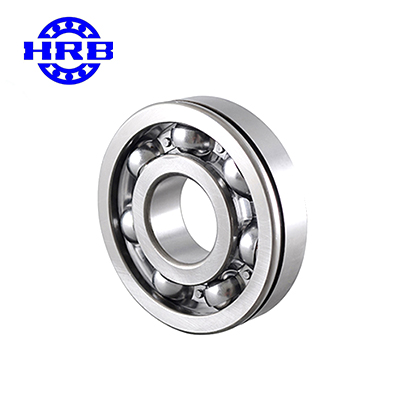

Self-aligning roller bearings feature two rows of rollers, primarily designed to handle radial loads while also accommodating axial loads in either direction. They offer high radial load capacity, making them particularly suitable for heavy-duty or vibration-prone applications, though they cannot withstand pure axial loads. The outer ring raceway is spherical, providing excellent self-aligning capability to compensate for misalignment errors.

They feature two symmetrical rows of spherical rollers. The outer ring has a common spherical raceway, while the inner ring has two raceways inclined at an angle to the bearing axis. This design provides excellent self-aligning capability, allowing the bearing to function normally even when the shaft is bent under load or mounted out of concentricity. The self-aligning capability varies with the bearing size series, with a typical allowable self-aligning angle of 1 to 2.5 degrees. This bearing type offers high load capacity, accommodating both radial loads and bidirectional axial loads while providing good shock resistance. Generally, self-aligning roller bearings have lower permissible operating speeds.

Self-aligning roller bearings are classified into two distinct structures based on roller cross-section shape: symmetrical spherical rollers and asymmetrical spherical rollers. Asymmetrical self-aligning roller bearings represent an earlier product generation, primarily serving maintenance needs for existing machinery. Symmetrical self-aligning roller bearings are rarely selected for new equipment designs. Comprehensively redesigned internal structures and optimized parameters enable these bearings to handle greater axial loads compared to earlier models. Operating at lower temperatures, they accommodate higher rotational speeds. Based on flange presence on the inner ring and cage type, they are categorized as Type C or Type CA. Type C bearings feature a flangeless inner ring and stamped steel cages. while CA-type bearings feature flanges on both sides of the inner ring and a machined solid cage.

Self-aligning roller bearings are categorized by bore type: cylindrical bore or tapered bore. When mounted on a matching locking sleeve, they become K+H type and K30+H type bearings.

These bearings can be mounted on shafts without shoulders and are suitable for applications requiring frequent bearing installation and removal. To enhance lubrication performance, the outer ring is machined with a circumferential oil groove and three evenly spaced oil holes, designated with the suffix W33.

“Do you see over yonder, dear client, those tricky equipment bottlenecks, those wear-and-tear troubles that stall your production? I intend to arm your machines with genuine imported bearings—and stand by with technical support to slay every glitch that comes your way.”

— Hengzhou Bearings

leave a comment