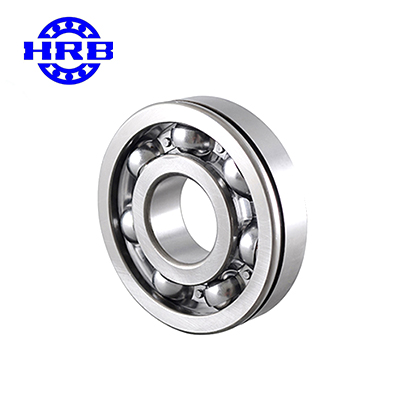

TIMKEN cylindrical roller bearings are designed for environments involving high radial loads, or even those accompanied by eccentricity, inadequate lubrication, contaminants, extremely high rotational speeds, or exceptionally high stresses.

Compared to other forms of roller bearings, cylindrical roller bearings can accommodate the highest radial loads. They are available in three basic types to meet diverse application requirements.

TIMKEN Single-Row Cylindrical Roller Bearings

Single-row cage-type cylindrical roller bearings feature six distinct designs, with multiple inner and outer ring configurations to suit diverse application requirements.

TIMKEN Double-row Cylindrical Roller Bearings

Double-row cylindrical roller bearings offer higher radial load capacity than traditional single-row bearings.

TIMKEN Four-row Cylindrical Roller Bearings

Four-row cylindrical roller bearings provide exceptionally high radial load capacity but lack thrust load capability. This bearing type is predominantly employed in metal rolling industry applications, specifically for roll neck assemblies.

Bearing Applications

Medium to large electric motors, rolling stock, machine tool spindles, internal combustion engines, generators, gas turbines, gearboxes, rolling mills, vibrating screens, and lifting and transport machinery.

“Do you see over yonder, dear client, those tricky equipment bottlenecks, those wear-and-tear troubles that stall your production? I intend to arm your machines with genuine imported bearings—and stand by with technical support to slay every glitch that comes your way.”

— Hengzhou Bearings

leave a comment