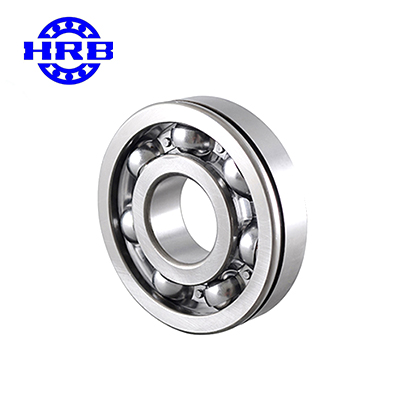

INA needle roller bearings are roller bearings featuring cylindrical rollers that are slender and elongated relative to their diameter. These rollers are termed needle rollers. Despite their small cross-section, the bearings exhibit high load-carrying capacity, rendering them particularly suitable for applications where radial space is restricted. Depending on the application, bearings without an inner ring or needle roller and cage assemblies may be selected. In such cases, the shaft journal surface and housing bore surface directly serve as the bearing's inner and outer rings. Depending on the application, either bearings without an inner ring or needle roller and cage assemblies may be selected. In such cases, the mating shaft journal surface and housing bore surface directly serve as the bearing's inner and outer rolling surfaces. To ensure equivalent load capacity and operational performance to bearings with rings, the hardness, machining accuracy, and surface finish of the shaft or housing bore raceway surfaces should be comparable to those of the bearing ring raceways. Such bearings can only accommodate radial loads.

Precautions

1. The roundness of the shaft and housing bore, along with the perpendicularity of the shoulder, must meet the corresponding precision requirements of the bearing.

2. Both the interference fit for the rotating ring and the appropriate fit for the fixed ring must be precisely calculated. Where feasible, the interference fit for the rotating ring should be kept as small as possible. Provided the effects of thermal expansion at operating temperatures and centrifugal forces at high rotational speeds are adequately accounted for, creep or sliding of the interference-fit surfaces can be avoided. For the non-rotating ring, select either a minimal clearance fit or an interference fit based on the magnitude of the operating load and bearing dimensions. Excessively loose or tight fits are detrimental to maintaining the original precise geometry.

3. For needle roller bearings operating at high speeds under elevated temperatures, particular attention must be paid to ensuring the rotating ring's fit is not excessively loose to prevent eccentric vibration. Similarly, the fixed ring's fit must be free of clearance to avoid deformation under load and subsequent vibration excitation.

Rolling bearings may exhibit slight operational noise during service. Excessive noise, abnormal sounds, or impact noises indicate bearing failure.

“Do you see over yonder, dear client, those tricky equipment bottlenecks, those wear-and-tear troubles that stall your production? I intend to arm your machines with genuine imported bearings—and stand by with technical support to slay every glitch that comes your way.”

— Hengzhou Bearings

leave a comment