The roller-type one-way clutch comprises an outer ring, rollers, springs, and an inner ring, typically featuring 6 to 8 rollers. During operation, should the outer ring rotate counter-clockwise relative to the inner ring, the rollers will traverse the cam-shaped grooves towards the larger end, thereby compressing the springs. At this stage, the one-way clutch exhibits no locking behaviour and permits rotation of the outer ring. In essence, the clutch consistently allows counter-clockwise rotation of the outer ring relative to the inner ring. Alternatively stated, it permits the inner ring to rotate clockwise relative to the outer ring.

However, during operation, should the outer ring attempt clockwise rotation relative to the inner ring, the rollers move towards the smaller end within the open groove. They wedge between the inner and outer rings, locking them together while simultaneously transmitting torque between them. At this point, the spring enhances the initial wedging action of the rollers. Once the rollers wedge into the small end of the open groove, the one-way clutch locks, preventing the outer ring from rotating clockwise relative to the inner ring or the inner ring from rotating anticlockwise relative to the outer ring.

The contact surface between the outer ring and the rollers is formed as a cam-type surface with a specific wedging angle. In existing designs, this angle typically ranges from 6 to 8 degrees. To maintain a constant wedge angle within the contact zone while accounting for machining tolerances and operational wear, the cam surface profile of the opening groove is often machined as a logarithmic spiral.

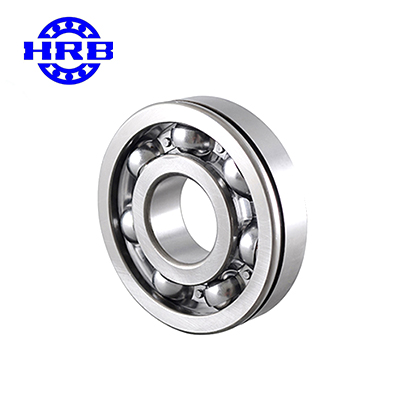

During operation of the roller-type one-way clutch, the maximum contact stress occurs at the points where the rollers engage with the inner and outer rings. Strictly speaking, since the forces acting on both sides of the roller are equal, and its contact area with the inner ring's convex surface is smaller than that with the outer ring's concave surface, the maximum contact stress occurs on the contact surface between the roller and the inner ring. Here, surface fatigue wear is most likely to occur, with pitting and spalling being typical failure modes. The metallic materials used to manufacture the rollers and inner/outer rings of one-way clutches are generally the same as those for rolling bearings.

“Do you see over yonder, dear client, those tricky equipment bottlenecks, those wear-and-tear troubles that stall your production? I intend to arm your machines with genuine imported bearings—and stand by with technical support to slay every glitch that comes your way.”

— Hengzhou Bearings

leave a comment