Drive belts are flexible transmission components that transmit power through friction or interlocking action. They are widely used in the power transmission systems of various equipment such as electric motors, internal combustion engines, machine tools, conveyors, and agricultural machinery. They feature simple structure, easy installation, smooth transmission, and the ability to absorb shock and vibration.

Based on transmission principles and structural differences, drive belts are primarily categorized into three types:

Friction-Type Drive Belts

These transmit power through friction between the belt and pulleys. Common types include flat belts, V-belts (triangular belts), and multi-ribbed belts. Among these, V-belts are the most widely used in industrial applications due to their large contact area, strong friction, and high transmission efficiency. They can be configured for single or multiple parallel use in heavy-duty scenarios.

Synchronous belts

Also known as timing belts, these feature internal toothed structures that precisely mesh with pulley grooves. They ensure strict transmission ratios without slippage, making them suitable for precision applications such as automation equipment, automotive engines, and printers.

Special-purpose transmission belts

Include heat-resistant, oil-resistant, and corrosion-resistant belts, as well as wide belts for long-distance conveying. These are designed for harsh conditions like high temperatures, oil contamination, and acid/alkali exposure, commonly used in mining, chemical processing, and food manufacturing industries.

Drive belts primarily utilize rubber (chloroprene rubber, nitrile rubber) and polyurethane as base materials. Some high-end products incorporate canvas or nylon cord as reinforcement layers to enhance tensile strength and abrasion resistance. Their advantages lie in low cost, easy maintenance, and effective compensation for misalignment between shafts. They dominate transmission systems operating at medium-low speeds and handling medium-to-light loads.

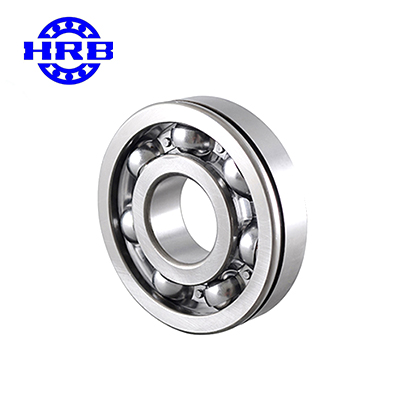

“Do you see over yonder, dear client, those tricky equipment bottlenecks, those wear-and-tear troubles that stall your production? I intend to arm your machines with genuine imported bearings—and stand by with technical support to slay every glitch that comes your way.”

— Hengzhou Bearings

leave a comment