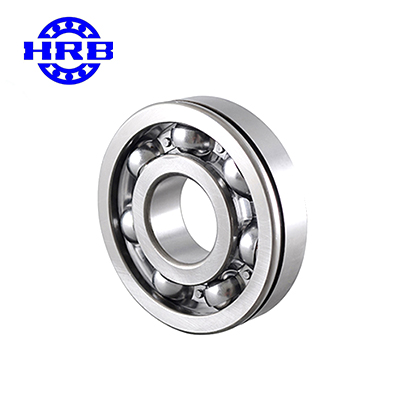

Features:

Compact size, high precision

The nut and support bearing are integrally formed, resulting in a compact nut size. The 45° contact angle of the support bearing enables high axial load capacity and high assembly precision.

Easy assembly

Simply secure the nut to the bearing housing with screws to obtain a rotary ball screw mechanism.

High Feed Rate

With the screw fixed, rotational inertia forces are eliminated. This enables high-speed feed even in long-to-diameter ratio ball screws, allowing selection of motors with lower drive power.

High Rigidity

The R1 series ball screws feature larger support bearings than conventional models, significantly enhancing axial rigidity.

Low Noise

The R1 series employs end cap recirculation, with recirculating balls flowing back within the nut. This design produces lower noise levels than conventional screws even during high-speed rotation.

Applications

Semiconductor machinery, industrial robots, woodworking machines, laser processing machines, material handling equipment.

“Do you see over yonder, dear client, those tricky equipment bottlenecks, those wear-and-tear troubles that stall your production? I intend to arm your machines with genuine imported bearings—and stand by with technical support to slay every glitch that comes your way.”

— Hengzhou Bearings

leave a comment